- Home

- Laser welding

- Blue Laser Welding Machine

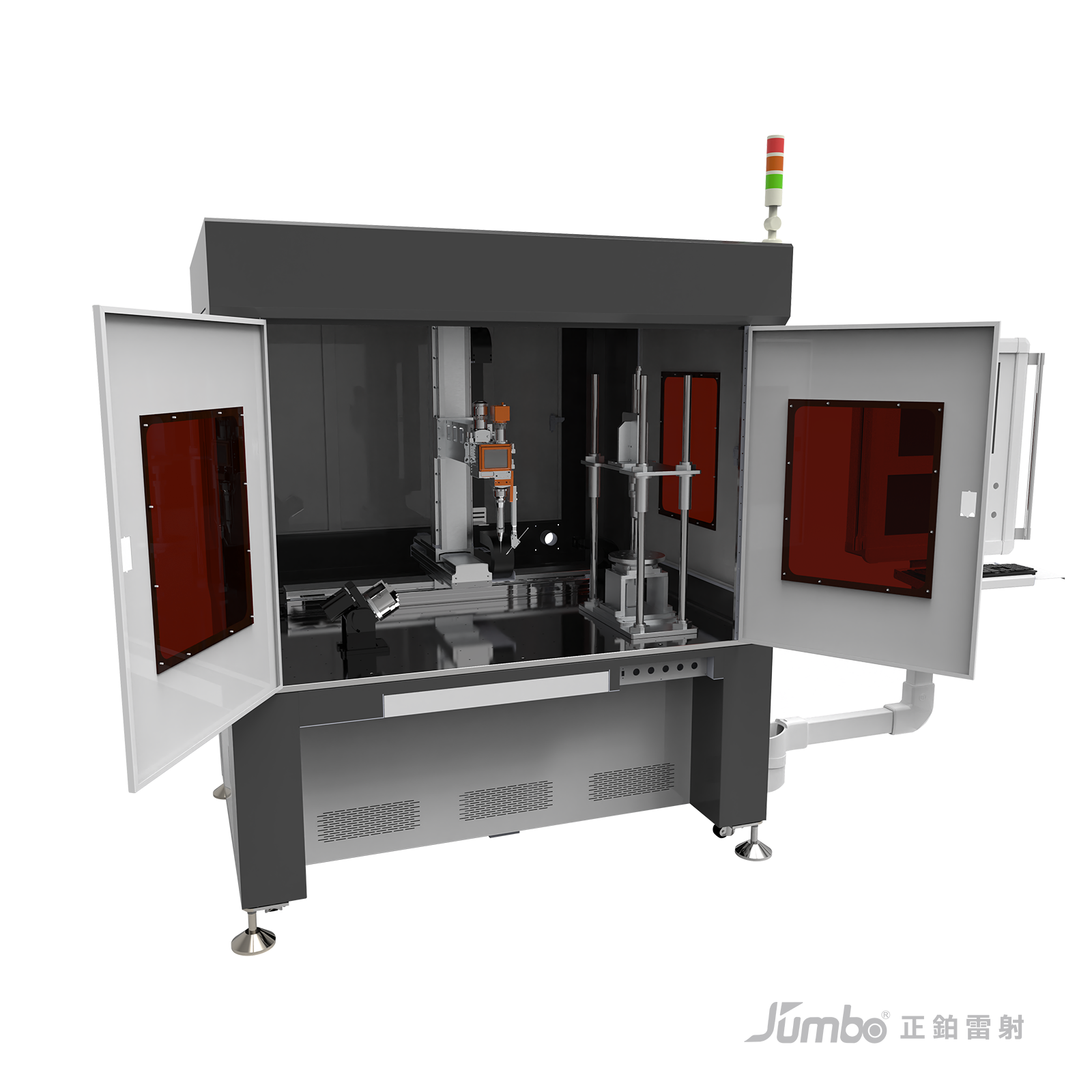

Blue Laser Welding Machine

-

● High Absorption & Precision Processing

With its shorter wavelength, blue laser offers higher absorption in reflective metals such as copper and aluminum, enabling high-precision micro welding and deep penetration welding with strong, reliable joints. -

● Minimal Heat-Affected Zone (HAZ)

The small HAZ reduces thermal distortion or damage, making it ideal for welding thin-walled materials and delicate components. -

● High Efficiency & Stability

Its high energy density shortens processing time and increases welding speed, making it suitable for high-volume, continuous production. -

● Excellent Integration with Automation

Easily integrated with robotic arms and automated systems to build smart welding lines that enhance accuracy and consistency. -

● Versatile Industrial Applications

Widely used in industries requiring high precision and reliability, such as electronics, automotive (e.g., EV motor copper welding), medical devices, and aerospace.

-

Product number

-

JBL-LMF

-

-

Application Introduction

-

Widely used in industries requiring high precision and reliability, such as electronics, automotive (e.g., EV motor copper welding), medical devices, and aerospace.

-

-

-

Equipment Specifications

-

Laser source power :800W

Processing range :40*40mm

Work Environment :10~45℃ , <70%

power supply :3kw / AC220V

Cooling method :Water Cooling

Equipment weight : 800kg

Equipment size :1300*1500*1800mm -

-