- Home

- Laser marking

- Fiber laser marking series

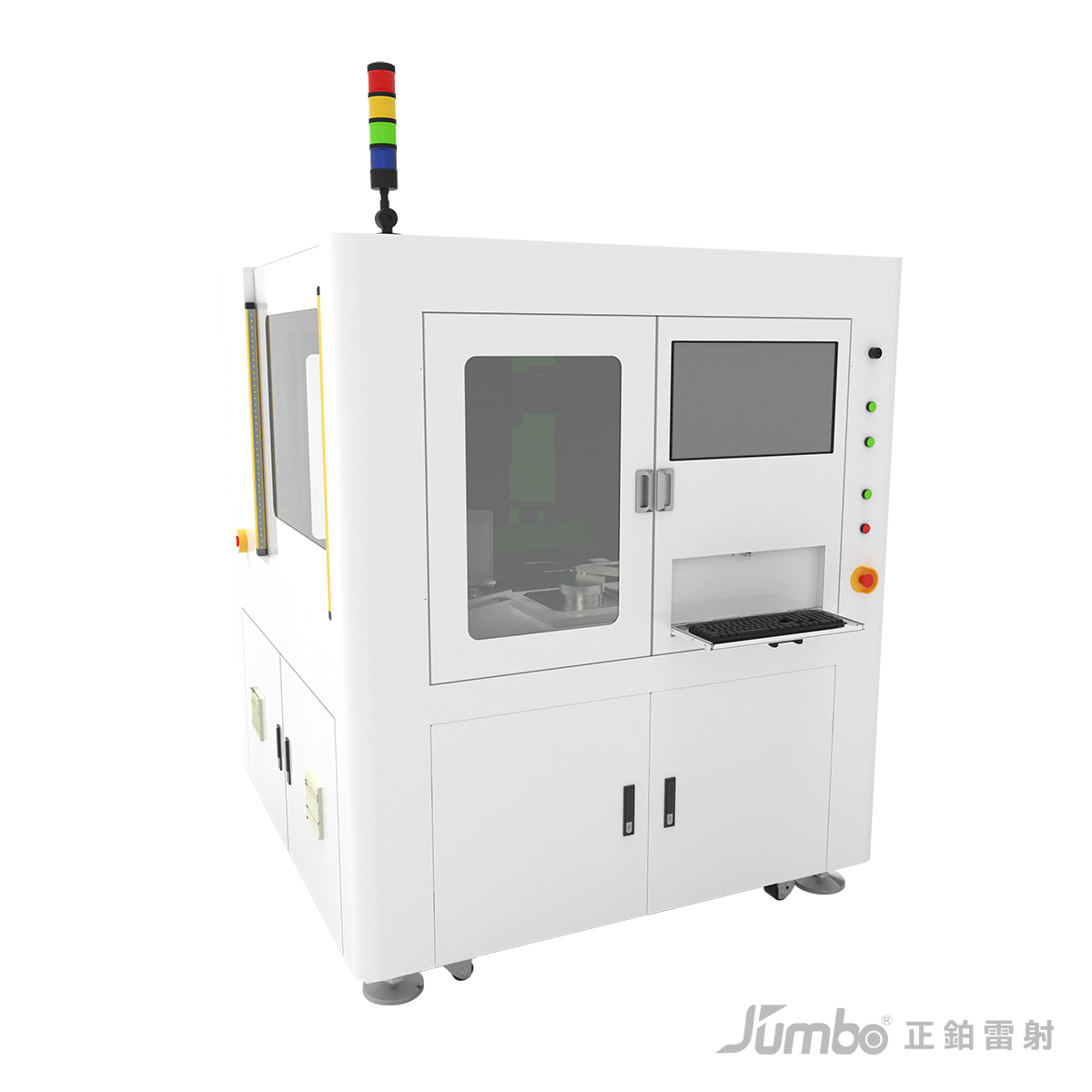

- Automated Laser De-Molding System for Reclaimed Wafers

Automated Laser De-Molding System for Reclaimed Wafers

-

Supports Reclaimed Wafer Processing:

The equipment is suitable for wafer grinding and cleaning processes, enabling the reuse of wafers that do not meet IC manufacturing standards or are used as dummy/control wafers. This helps reduce testing costs and improve resource utilization. -

Reduces Environmental Impact:

Wastewater generated during the grinding process—containing silicon particles and chemical substances—can be managed with wastewater treatment modules, minimizing potential environmental harm. -

Meets High-Demand Application Fields:

Reclaimed wafers are ideal for process development in industries such as solar energy and silicon-based semiconductors, fulfilling testing and monitoring requirements while enhancing overall process efficiency. -

Built-in Laser Micromachining Module:

Equipped with high-precision laser marking capabilities, the equipment can directly mark serial numbers, QR codes, and other production traceability data on wafers, ensuring accurate and reliable identification. -

Complies with Semiconductor Process Standards:

The laser marking technology offers high durability and resistance to harsh processing conditions, making it especially suitable for high-standard environments such as packaging and testing stages.

-

Product number

-

JBL-LMF

-

-

Application Introduction

-

Widely used in industries requiring high precision and reliability, such as electronics, automotive (e.g., EV motor copper welding), medical devices, and aerospace.

-

-

-

Equipment Specifications

-

Laser source power :800W

Processing range :40*40mm

Work Environment :10~45℃ , <70%

power supply :3kw / AC220V

Cooling method :Water Cooling

Equipment weight : 800kg

Equipment size :1300*1500*1800mm -

-